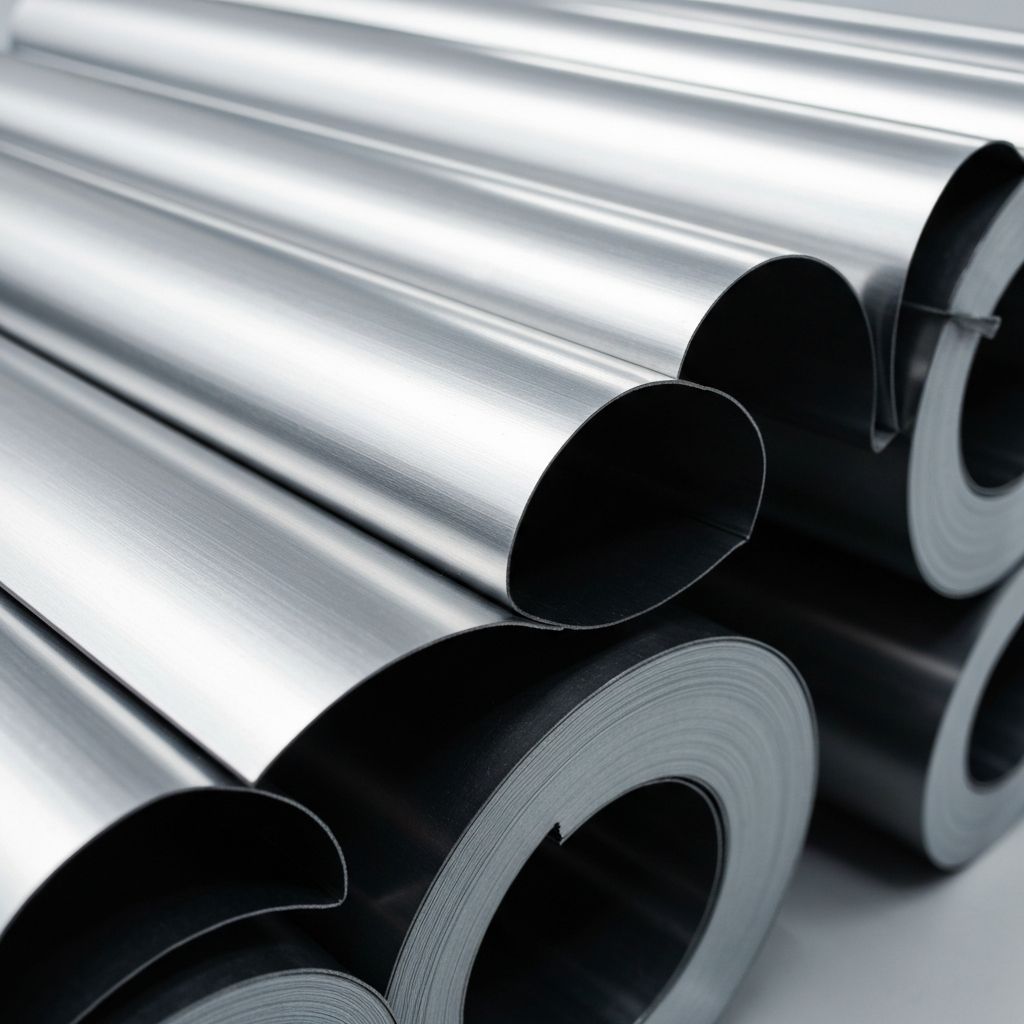

HR / CR Coils

Hot Rolled and Cold Rolled steel coils for every fabrication need

What Steel Coils Are Used For

Steel coils are the foundation of modern fabrication. They're used for everything from structural frames and heavy industrial builds to precision-formed components and machine parts. HR coils provide strength and toughness for demanding jobs, while CR coils deliver accuracy and clean surfaces for detailed work.

Hot Rolled Coils for Heavy Work

Hot Rolled coils are made for strength and durability. They're perfect for structural work, frames, brackets, platforms, and heavy fabrication where the material needs to handle serious load and stress. HR coils are easier to form when hot and are well-suited for welding and large-scale construction needs.

Cold Rolled Coils for Precision

Cold Rolled coils offer a smooth, clean finish and tight dimensional accuracy. They're the go-to choice for precision fabrication, cabinets, machine housings, panels, and anything requiring consistent thickness and a polished look. CR coils help manufacturers get cleaner cuts, sharper bends, and better final results.

Perfect for Forming, Cutting, and Shaping

Both HR and CR coils are easy to work with using cutting, bending, stamping, and forming processes. HR coils handle the tough jobs, while CR coils excel in fine detail. This makes them ideal for workshops that produce everything from large structures to small, accurate components in volume.

Consistent Quality for Industrial Production

Every coil goes through controlled manufacturing and inspection to ensure it arrives with the right thickness, finish, and straightness. Reliable coils reduce waste, speed up production, and help maintain high quality on every job — from construction to precision manufacturing.